Sinoma Energy Conservation (Wuhan) Co., Ltd.

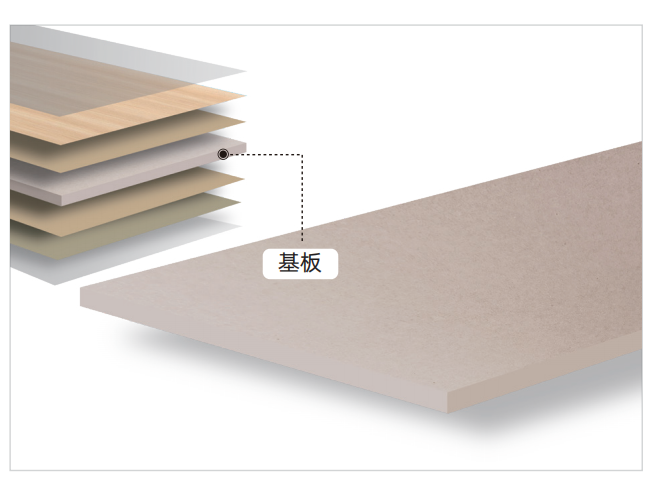

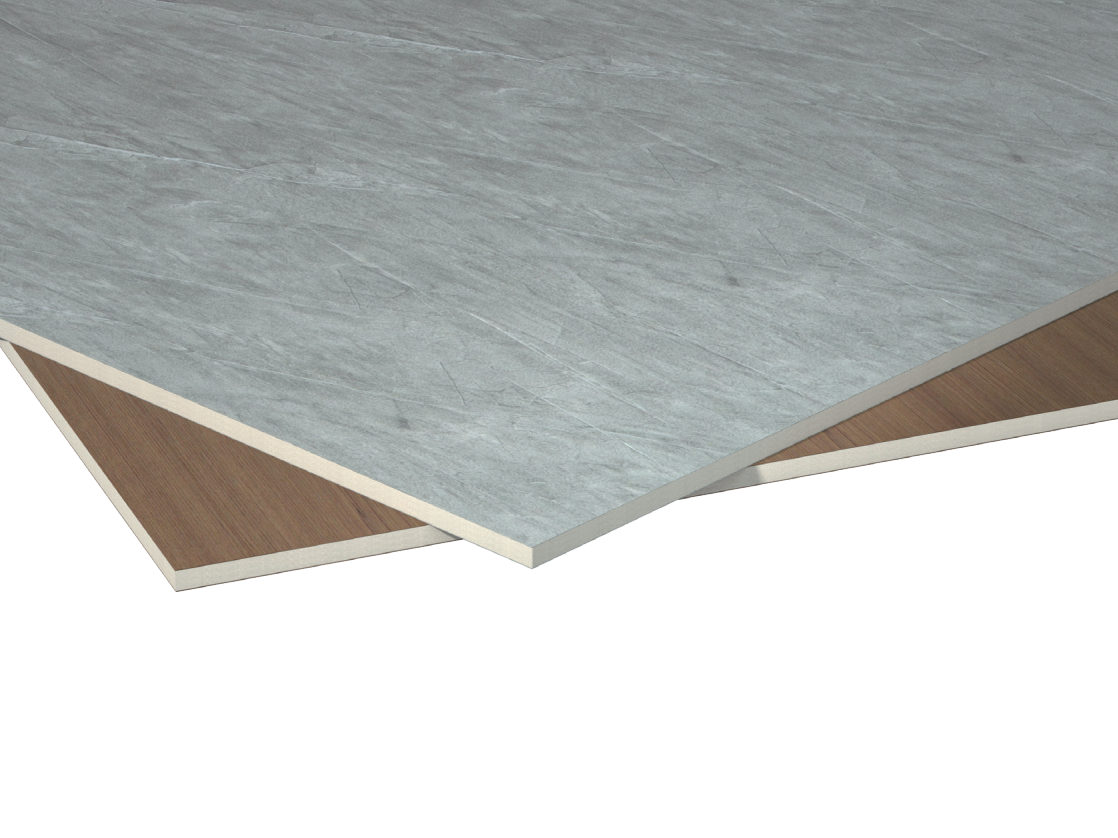

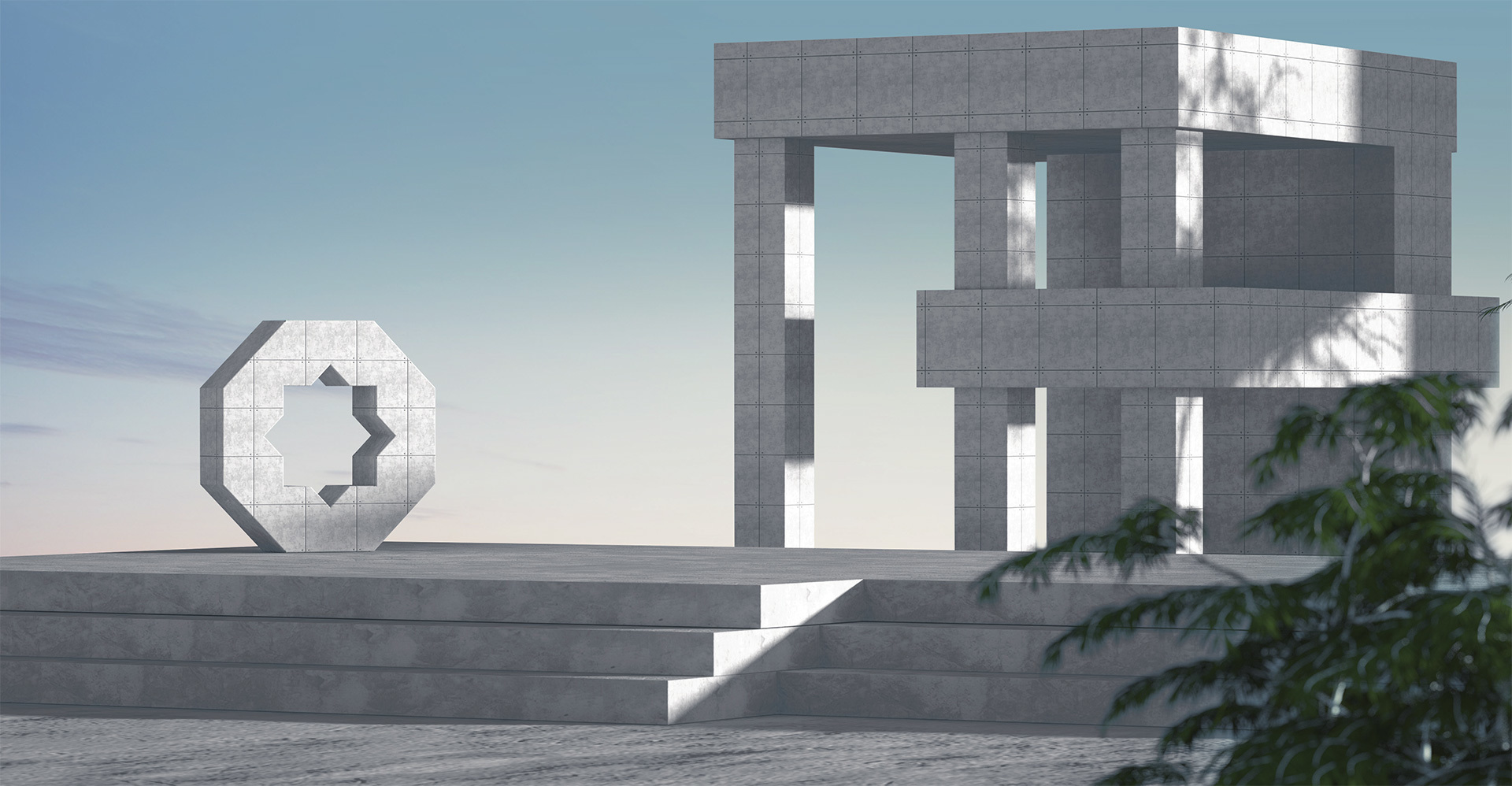

Sinoma Energy Conservation (Wuhan) Co., Ltd., affiliated with China National Building Material Group Co., Ltd., is a wholly-owned subsidiary of Sinoma Energy Saving Co., Ltd., which is itself a controlling company under the group. Operating at the third-tier management level within the group, the company has a registered capital of 191 million yuan. Its core business revolves around high-end calcium silicate board products, making it a large-scale, integrated industrial platform company that combines investment, product R&D, manufacturing, and sales. The company has established multiple production facilities both domestically and internationally.

App Overview

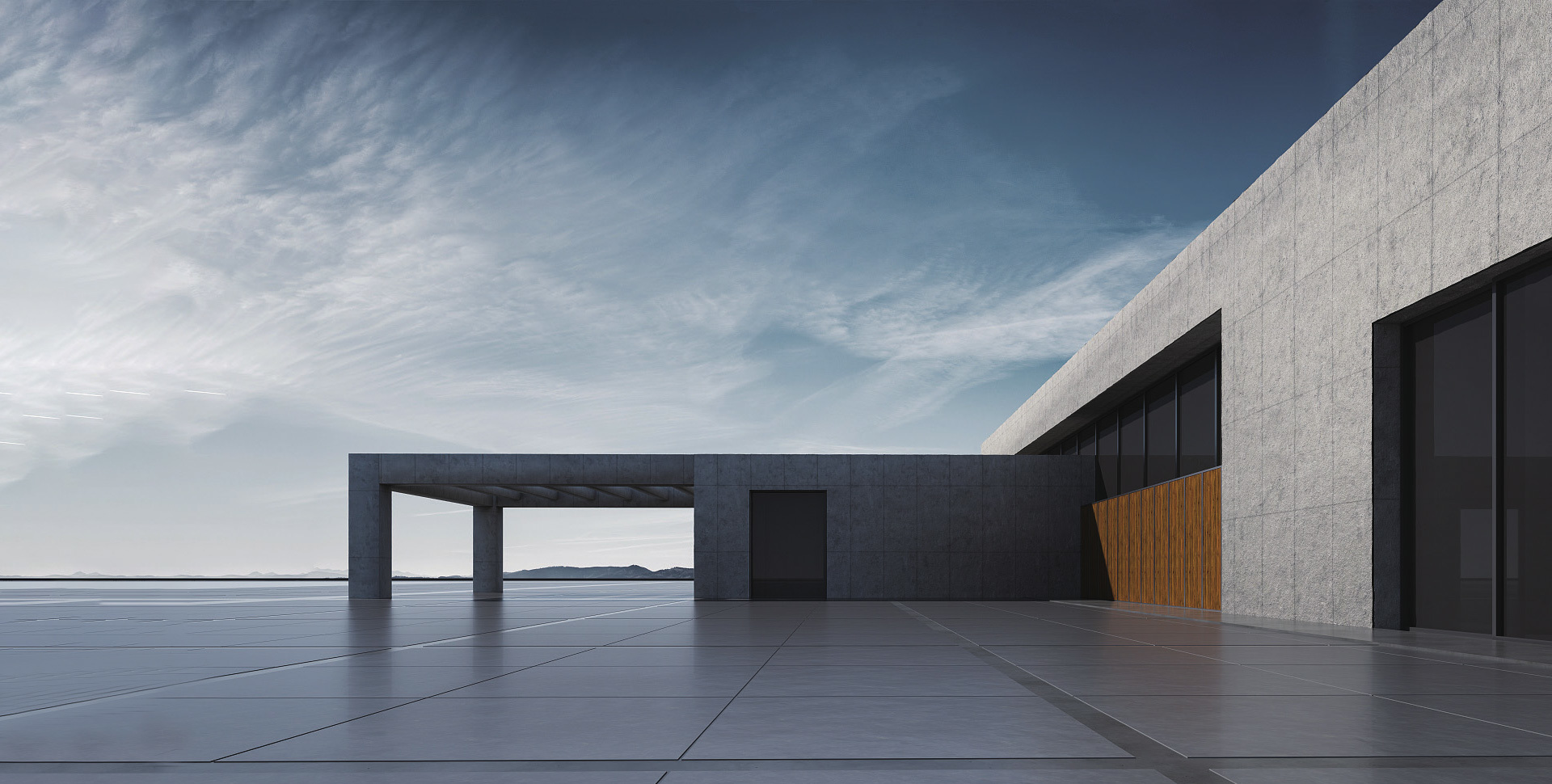

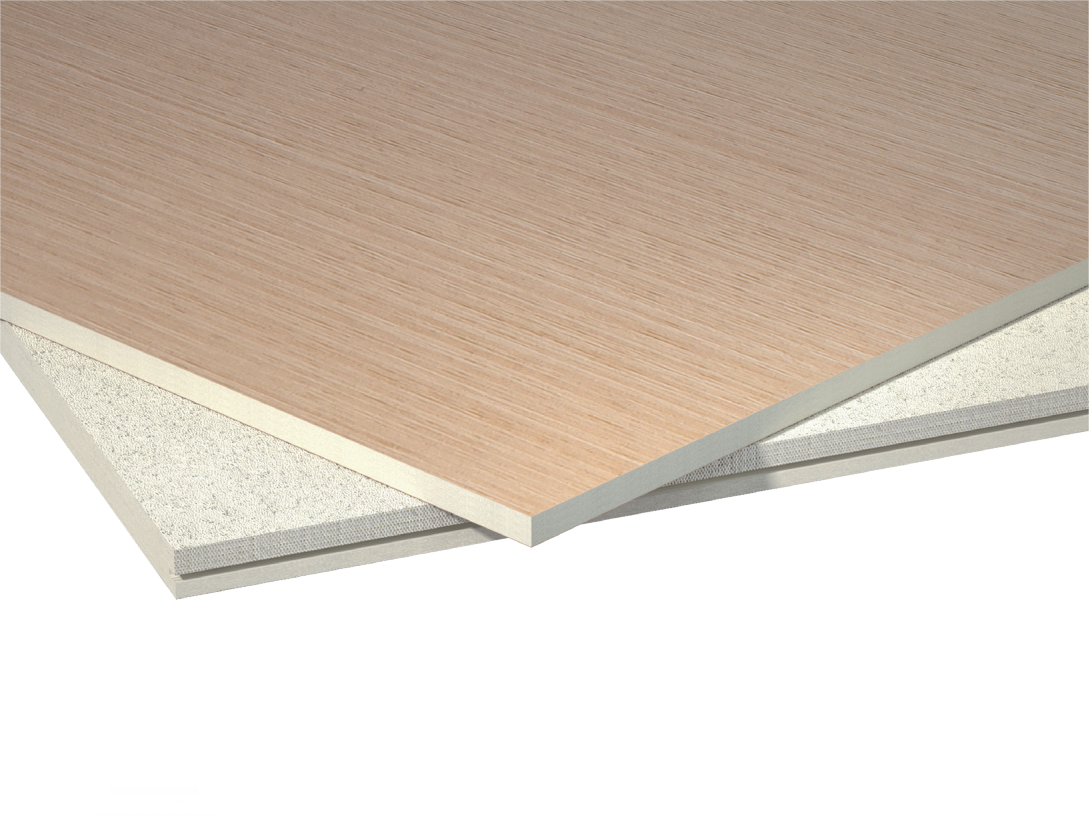

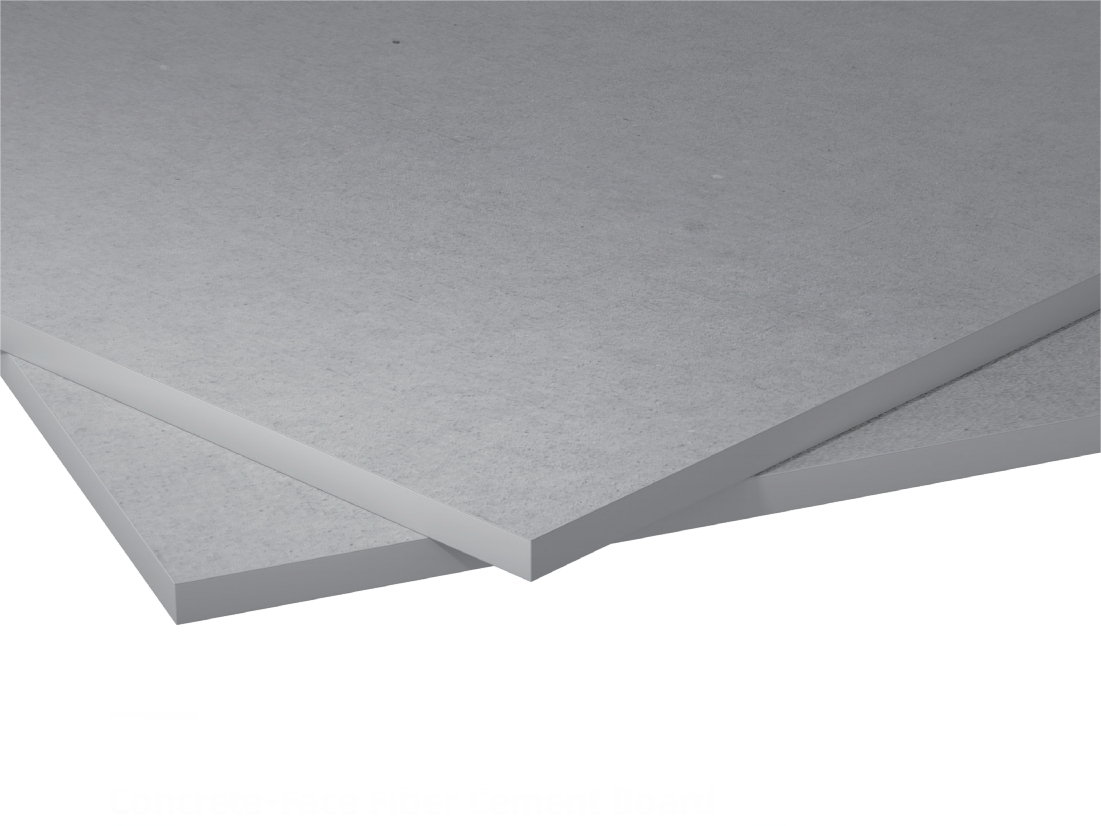

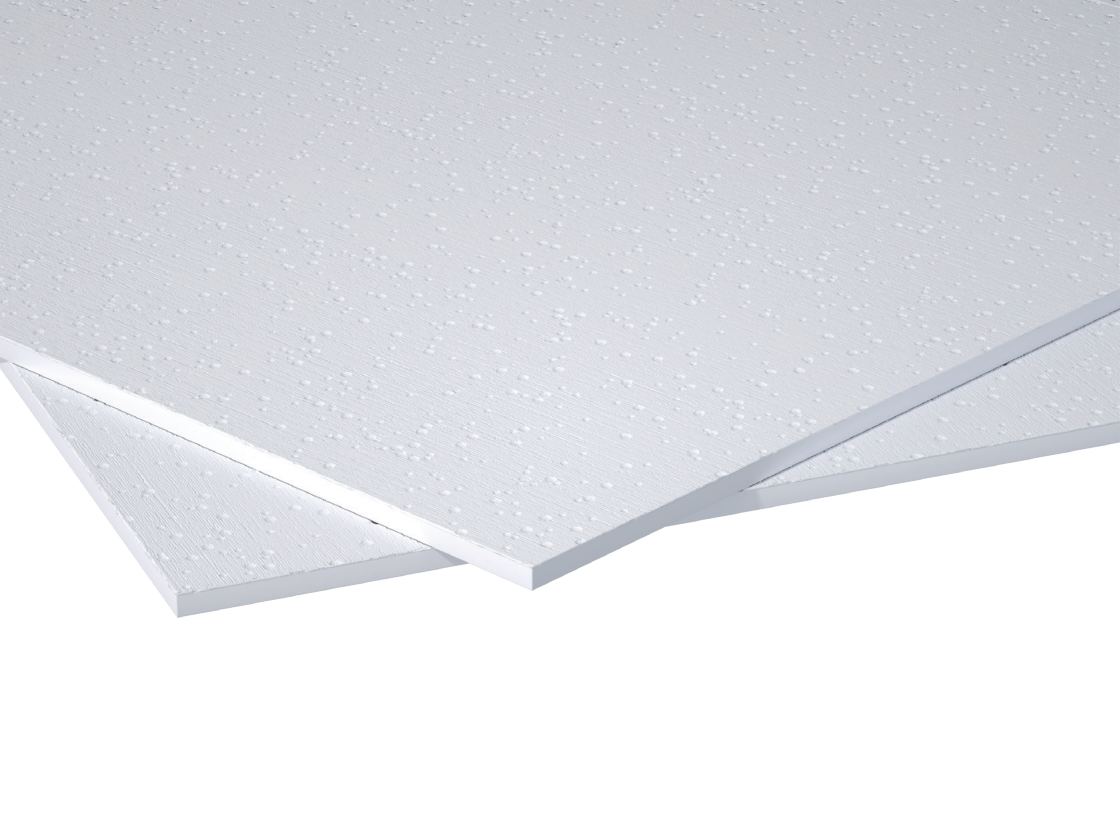

Standardized, integrated, and modular installation systems drive the adoption of prefabricated interiors—environmentally friendly, aesthetically pleasing, employing dry construction methods, and designed for easy disassembly and reuse, paving the way for sustainable building development.

News Updates

Party building work

Contact Information

Phone:027-65521781(Office phone)

027-65521935(Calcium Silicate Board Division) /027-65522625(Decorative Panel Division)

Email:baifeng@sinoma-ec.cnlijie@sinoma-ec.cn

WeChat Official Account

WeChat Video Channels

Official TikTok

Product Color Chart