On June 13, 2019, the 2019 Annual Meeting of the Calcium Silicate Cement Board Branch of China Concrete and Cement Products Association was held in Tonglu, Zhejiang. The conference was hosted by the Calcium Silicate Cement Board Branch of China Concrete and Cement Products Association, co-organized by Zhejiang Handbang Building Materials Co., Ltd., Wuhan Building Materials Industry Design and Research Institute Co., Ltd., Foshan Xingdongle Machinery Manufacturing Co., Ltd., and Guangdong Shunde Difeng Machinery Co., Ltd. support. The theme of the conference was "seeking common quality improvement and promoting the long-term development of the industry.

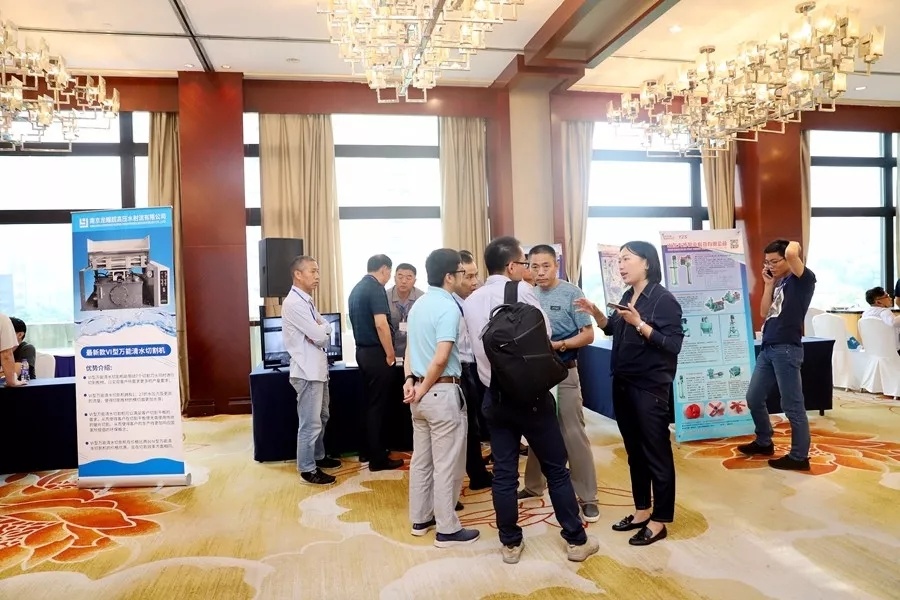

Meeting site

Yao Yuanjun, Vice President of China Concrete and Cement Products Association, Chairman of Calcium Silicate Cement Board Branch, Chairman of Wuhan Building Materials Industry Research Institute Co., Ltd., Shi Linzhong, Vice President of China Concrete and Cement Products Association, Vice President of Calcium Silicate Cement Board Branch, General Manager of Jiangsu Aifuxi New Building Materials Co., Ltd., Secretary-General Zeng Qingdong of China Concrete and Cement Products Association, Deputy Secretary-General Shen Bing, Zhejiang Handebang Building Materials Co., Li Yungang, shen Jianxin, Liu Wenhua, Xiong Yan, Ye Musheng, Zhou Liangjian, Chen Hui, Chen Jingxin, Anhui Haichuang New Energy-saving Building Materials Co., Ltd. and other representatives of vice-chairman units, Shi Zhiqiang, a specially invited report expert, and more than 200 representatives of branch member enterprises attended the meeting. The meeting specially invited Ye Liming, director of Tonglu County Office for the Development of New Wall Materials, to attend and deliver a speech. The conference was presided over by Wang Hanhong, Secretary General of China Concrete and Cement Products Association Calcium Silicate Cement Board Branch.

Ye Liming, Director of Tonglu County Office for the Development of New Wall Materials

In his speech, Director Ye Liming introduced that in recent years, Tonglu County has always adhered to the innovation road of government guidance and enterprise entities, and actively promoted the resource utilization of solid waste in the production of new wall materials. For example, Zhejiang Handbang Building Materials Co., Ltd. has been Committed to the development and research of new wall materials and solid waste recycling, leading the development of the industry. At present, 12 products of 8 enterprises in the county have been identified as provincial "green building materials products", and 3 production lines have won provincial new wall material production demonstration lines and two provincial new wall material leading enterprises. Yongdong Building Materials was awarded the first batch of national construction waste resource utilization demonstration bases, Handbang Building Materials was awarded the national new wall material energy-saving and emission-reduction demonstration enterprise, and Yongdong Building Materials and Yuanchuang Technology were also awarded the "Twelfth Five-Year" national wall material innovation and innovation benchmark enterprise.

Shen Bing, Deputy Secretary General of China Concrete and Cement Products Association

In his speech, Deputy Secretary-General Shen Bing first congratulated Wang Hanhong on his appointment as the Secretary-General of the Calcium Silicate Cement Board Branch of China Concrete and Cement Products Association. Deputy Secretary-General Shen Bing introduced in detail the new trend of the transformation and upgrading of the concrete and cement products industry to green and high-quality development.

Shen Bing introduced that the current new trend of transformation and upgrading of my country's concrete and cement products industry to green and high-quality development is mainly reflected in six aspects: the supply-side structural reform has achieved remarkable results, and green development has become a breakthrough in the transformation and development of the industry; the market concentration of key industries It has increased; the number of PC industry enterprises has grown rapidly; technological innovation has driven new products and new applications; green development has become a breakthrough in industry transformation and development; the problem of raw materials has become a factor influencing the current steady growth of the industry.

Yao Yuanjun, Chairman of the Branch

In his speech, Chairman Yao Yuanjun pointed out that at present, the national industrial policy vigorously supports the development of green environmental protection and ecology. In the building materials industry policy promulgated by the state, calcium silicate board/fiber cement board has been listed as a "green environmental protection" new building material product, which is healthy and sustainable for the industry. Development will have a positive role in promoting and is a new opportunity for industry development. At present, China's calcium silicate fiber cement board production line is about 10% growth every year, with a production capacity of about 1 billion square meters. It should be said that our industry is a thriving industry, and it is also an industry that stands upright and spreads its wings in the wind.

Li Yungang, General Manager of Zhejiang Handbang Building Materials Co., Ltd.

General Manager Li Yungang, on behalf of Zhejiang Handbang Building Materials Co., Ltd., the co-organizer of the meeting, welcomed the guests to Tonglu County, the "most beautiful county in China. He introduced that Handbang Building Materials adheres to the corporate philosophy of "making every building adopt green, safe and energy-saving building materials" and is committed to the development and application of new building products. We are willing to work with colleagues from all walks of life to promote the innovation of environmental protection in China's construction industry, improve the integrated innovation ability of the construction industry, realize the standardization of new architectural design, the factorization of component production, the mechanization of construction, the scientific combination management, and the integrated application of new technologies. make unremitting efforts to create a beautiful and comfortable living space!

Branch Secretary-General Wang Hanhong

Secretary-General Wang Hanhong made a detailed analysis and introduction of the current situation of China's calcium silicate cement board industry and introduced the branch's 2019 work plan. Wang Hanhong introduced that the calcium silicate cement board industry in 2018 can be summarized by keywords such as "hot", "exuberant", "supply in short supply" and "international exchange. In 2019, the calcium silicate cement board industry should focus on: seeking common quality improvement and promoting the long-term development of the industry!

As of the end of 2018, according to incomplete statistics, there are about 130 enterprises producing calcium silicate cement boards in China, with nearly 210 production lines, a production capacity of nearly 1 billion square meters (excluding those under construction and not put into production), and an output of less than 0.6 billion square meters. Compared with 2017, the production line increased by more than 10%. However, the output basically did not increase. The decline in output was mainly due to the impact of environmental protection, rising prices of raw materials and low-price competition in the market. Some enterprises stopped production, while some enterprises made low-density boards, diatomite boards and full-body boards, which reduced the output. The output of coated board (including integrated board) in 2018 is about 4500-5000 square meters, and the production capacity is about 0.1 billion square meters, which has an impact on the supply chain of substrates.

Jiangsu Aifu Xi New Building Materials Co., Ltd. Chairman Assistant Shi Zhiqiang

The meeting invited Shi Zhiqiang, assistant to the chairman of Jiangsu Aifuxi New Building Materials Co., Ltd., to make a special report on "the current situation and future development of China's fiber cement board and calcium silicate board industry".

Shi Zhiqiang introduced the development of fiber cement board and calcium silicate board enterprises and production lines in my country in the past 12 years, as well as the main product types, and analyzed the current problems in the industry. At present, the industry has serious overcapacity, and the actual production and sales are only 40% of the total production capacity, but the supply of products that the market really needs is insufficient.

Shi Zhiqiang analyzed the future development trend of China's fiber cement board and calcium silicate board industry: asbestos-free is the general trend; Environmental protection in production plants will be further upgraded; Products will be more abundant and diversified; Industry concentration will increase; The market is becoming more and more rational. In the future, fiber cement board and calcium silicate board have great potential as alternative materials in the fields of woodworking board, plywood, glass magnesium board, OSB board, waterproof and fireproof paper plaster board.

Wu Weiping, Deputy General Manager of Wuhan Building Materials Industry Design and Research Institute Co., Ltd.

Wu Weiping, deputy general manager of Wuhan Building Materials Industry Design and Research Institute Co., Ltd., introduced the application of grass pulp fiber in fiber cement board. Wu Weiping introduced that wood pulp fiber is a material that has a greater impact on the performance and cost of the board. At present, domestic wood pulp fiber mainly relies on imports. The price of wood pulp fiber is affected by international politics and economy, and fluctuates greatly. Therefore, the development of new alternative plants Fiber is conducive to controlling the production cost of enterprises and providing more material choices. The Technology Center of Wuhan Building Materials Industry Design and Research Institute Co., Ltd. cooperated with Professor Ying Hanjie's research group of the National Biochemical Engineering Technology Research Center of Nanjing University of Technology in 2018 to study the application of straw pulp fiber in fiber cement board.

Wu Weiping concluded that at present, the fiber cement board prepared by partial replacement or full replacement of wood pulp fiber has excellent performance, physical properties, mechanical properties and frost resistance can be close to pure wood pulp fiber cement board, and can reduce the cost by about 28.3-36.7. However, the straw pulp fiber will improve the porosity and water absorption of the board, and the straw pulp fiber has obvious water retention effect, and the board after suction filtration has high water content, which is not conducive to industrial production. The industrial production of straw pulp fiber will be further studied.

Lin Zhen, Director of Silicon Fiber Cement Technology Center in Elkem, Norway

Lin Zhen, director of the Technology Center for Silicon Fiber Cement in Elkem, Norway, introduced the reinforcement mechanism and failure causes of fiber composites. Lin Zhen concluded that the material characteristics of fiber-reinforced composite materials determine that its failure mode is completely different from brittle materials such as concrete. In addition to selecting appropriate basic cementitious materials and curing system, it is very important for the selection of reinforcing fibers. If reinforcement is used, the elastic modulus of fibers should be at least 2 orders of magnitude higher than that of the substrate. The role of fibers in composite materials is affected by the physical characteristics and chemical indexes of fibers, in particular, it is necessary to consider the compatibility of materials and the actual dispersion effect of fibers. The use of auxiliary materials is indispensable for the production of fiber composite materials. It is very important to understand the characteristics and functions of each auxiliary material for making good use of materials. Silica powder has obvious effects on increasing product strength and improving product durability. Silica powder can effectively improve delamination and protect cellulose fibers at the same time, extend the service life of cellulose fibers.

Xu Dingfeng, Deputy General Manager of Jinqiang (Fujian) Building Materials Technology Co., Ltd.

Xu Dingfeng, deputy general manager of Jinqiang (Fujian) Building Materials Technology Co., Ltd., introduced the definition, product classification, production process, application characteristics and development suggestions of calcium silicate cement ceiling. Calcium silicate cement ceiling is an interior decoration board made of fiber reinforced calcium silicate board or fiber cement flat board as the base material, which is refined by cutting, constant thickness sanding, roller coating or spraying, silk screen printing or fine printing, drying, perforation or embossing, chamfering and stacking. With the rapid development of China's economy, labor costs have become higher and higher. Automation and mechanization have become the general trend of calcium silicate cement ceiling production. A calcium silicate cement board enterprise in Fujian has taken the lead in carrying out intelligent equipment transformation, realizing fully automated operations from upper plate, thickness grading screening, surface sanding, soil approval, spraying, roller coating, drying, silk screen printing, or roller printing, turning over, stacking, palletizing to packaging. The production line personnel have been reduced by 62.5, the production capacity has increased by 25%, and more importantly, the quality has been greatly improved.

Jia Jian, vice president of research and development of Guangdong new element board industry co., ltd.

Jia Jian, vice president of research and development of Guangdong New Element Board Co., Ltd., introduced the performance parameters of fiber reinforced calcium silicate board for fire prevention. Jia Jian introduced that the formulation of a product's performance parameters cannot be separated from its application field. It is clear that fiber reinforced calcium silicate board should meet different performance parameter requirements in various building parts, and develop and produce corresponding board products according to the performance parameter requirements. Such as outdoor roofing products, outdoor wall products, indoor wall products, indoor ceiling products, indoor fire prevention products, indoor anti-explosion products, indoor explosion relief products, indoor humidity control products, phase change energy storage products and marine products, etc., none of the plates are "all-round" and can meet these application fields. If the ordinary indoor board is applied outdoors, there may be delamination, cracking, deformation, shedding and other phenomena; if the natural conservation board is applied indoors, there may be plate deformation, plate seam and even plate cracking and other phenomena. The improper application of the board will seriously affect the image of the fiber reinforced calcium silicate board in the eyes of customers, hinder the application and development of the fiber reinforced calcium silicate board, and affect the market's recognition of the fiber reinforced calcium silicate board series products.

Zhang Yu, Chief Engineer of Binzhou Lvbang Board Industry Co., Ltd.

Zhang Yu, chief engineer of Binzhou Lvbang Board Co., Ltd., introduced the production process of polished finish of calcium silicate board. Zhang Yu introduced the development trend of calcium silicate board polishing, product production process control, polishing machine, product application and other aspects. At present, the polishing board used for interior decoration on the market is mainly high-density cement board, which has the advantages of high density, smooth and dense surface and easy polishing, smooth and delicate surface with brightness, and its disadvantages are heavy weight, fragile, difficult processing and inconvenient construction. In order to reduce the labor intensity of the construction, reduce the load of the building, so that the polishing board is more lightweight, the product is easy to cut, can be bent to do modeling and other advantages. After more than a year of hard work, Binzhou Lvbang Board has developed a lighter low-density polishing product, which has been introduced to the market and has been widely recognized and praised by users!

Zhu Haitao, Manager of R & D Department of Zhejiang Handbang Building Materials Co., Ltd.

Zhu Haitao, manager of R & D department of Zhejiang Handbang Building Materials Co., Ltd., introduced the colorful exterior wall hanging system. Colorful exterior wall point hanging system is a new product of Zhejiang handebang building materials co., ltd. and introduces an exterior wall facing system suitable for exterior wall point hanging and curtain wall. The colorful exterior wall point hanging system is composed of Ruilide decorative panel and aluminum alloy exterior wall point hanging system. The Ruilide exterior wall decorative panel is an exterior wall panel with Hante board as the substrate and the surface treated with decorative coating. The system has the advantages of safety and reliability, diversified finishes, strong weather resistance, A- level fire prevention, easy installation, and the same life as the building, which can effectively save materials and labor, and reduce project cost.

Dr. Peng Lei, Tianjin Fire Research Institute, Emergency Management Department

Dr. Peng Lei of Tianjin Fire Research Institute of Emergency Management Department introduced the research and application of fiber reinforced calcium silicate board in the fire prevention of fabricated steel structure buildings. The fire performance parameters of fiber-reinforced calcium silicate board, the fire resistance of main components of assembled steel structure under the protection of fiber-reinforced calcium silicate board, and the application of fire protection technology for assembled steel structure are introduced.

Peng Lei concluded that the fiber reinforced calcium silicate board has excellent fire resistance integrity and high temperature stability, and the assembled steel structure is protected from fire by composite coating with rock wool, which has good fire resistance integrity and heat insulation performance. Fiber reinforced calcium silicate board is easy to prefabricate into fire protection module components, which is convenient to transport and install. Through the combination of fire resistance test and finite element simulation, the fire resistance limit and fire protection construction method of the components and nodes in the main assembly steel structure building are determined, which meets the requirements of the current code and has strong operability.

Liang Baowei, General Manager of Shanghai China Residence Technology Co., Ltd.

Liang Baowei, general manager of Shanghai China Residence Technology Co., Ltd., made a report on "Assembled Interior is an Opportunity for Industry Transformation and Upgrading. He believes that the fabricated interior will gradually replace the traditional interior. Compared with the traditional decoration, the fabricated interior will put most of the work into the factory for processing, greatly reducing the on-site construction time, bringing faster decoration efficiency and more perfect delivery quality. Liang Baowei introduced in detail the seven major systems of interior parts of China Residence Technology: assembled top surface system, assembled partition wall system, assembled wall surface system, assembled water and electricity system, assembled floor system, overall toilet system and overall kitchen system.

Xu Xueqin, Deputy General Manager of Guangdong Matsumoto Green New Material Co., Ltd.

Xu Xueqin, deputy general manager of Guangdong Matsumoto Green New Materials Co., Ltd., made "From building materials to parts, the only way for the development of prefabricated enclosure walls". From building materials to assembled parts, Xu Xueqin put forward suggestions for industrial enterprises: from "two mentions and two reductions (improving efficiency and quality, reducing labor volume and energy consumption" to "two mentions and three reductions (improving efficiency and quality, reducing labor volume, energy consumption and construction waste"), customization and integration are inevitable trends. In view of the diversity and characteristics of prefabricated buildings, the enclosure wall must adhere to the industrialization thinking, that is, the standard formulation, design deepening, production supporting, installation and construction, information management, service maintenance and other links of the enclosure wall system must form industrialization. "Closed loop". Adhere to the standardization, modularization, factory and scale of the production and supporting of enclosure wall products, and find a balance between personalized customization and standardized production through "less modulus, more combination. Emphasis on integrated design and collaborative design, in the assembly design technology planning and program design stage, as a part of the manufacturer, must be deeply involved in the design, to avoid non-coordination and bring a series of late problems and cost impact.

Beixin Building Materials Jinbang Board Factory Director Liu Xianjun

North New Building Materials Jinbang Board Factory Director Liu Xianjun introduced Jinbang Board products. Jinbang board (fiber-reinforced cement exterior wall decorative hanging board) is a new type of low-carbon outer enclosure decoration system material that integrates functionality and decoration. The production line fully introduces foreign advanced complete sets of equipment and process technology. The products are vacuum extruded and formed with high degree of automation and stable performance. The physical and appearance performance indicators meet the requirements of domestic and foreign standards.

Guangdong Shunde Difeng Machinery Co., Ltd. Project Director Xie Qingfa

Xie Qingfa, project director of Guangdong Shunde Difeng Machinery Co., Ltd., shared the one-piece plate coating technology. He introduced that the application of intelligent technology to the coating of integrated boards has the following advantages: the central control center integrates one line and one control mode to realize the functions of whole line linkage control, interlocking, mutual protection, etc.; Integrated online monitoring provides visual support for the central control center, remote real-time visual management for the management, and visual support for remote technical support; Timely data collection, adding professional hardware modules, realize the collection and upload of data such as output/cost/pass rate, and provide data support; Remote technical support, through the addition of hardware expansion blocks, realize wired/wireless network connection, remote assistance in fault monitoring and troubleshooting, and obtain the latest and fastest software upgrade services.

Plate Development Forum

Then the meeting entered the board development forum and question session. The forum was presided over by Shi Zhiqiang. The guests at the meeting answered questions and discussed and exchanged relevant issues such as board development and expert reports of the meeting.

Conference Show Site