[Science Popularization] Why can the thermal insulation and decoration integrated board surpass the thin plastering system?

Release date:

2019-12-26

Author:

Source:

Integral Board Branch

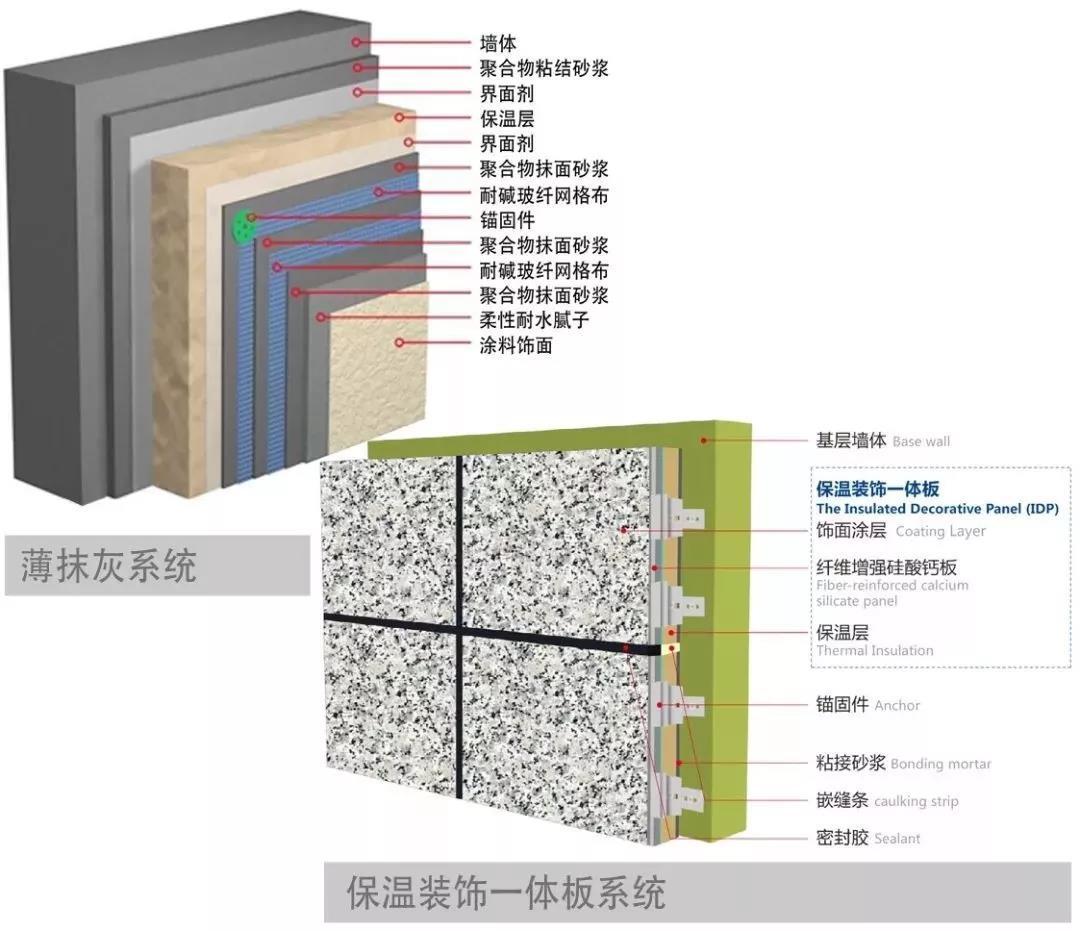

Building energy consumption is one of the three "big energy consumers" in China, and exterior insulation is one of the main ways to achieve building energy efficiency. In this situation, the state has put forward higher and higher requirements for the external insulation technology of building exterior walls, which has spawned many external insulation systems using different materials and different structural practices. For example, thin plastering system, curtain wall system and thermal insulation decorative integrated board. Among them, the system with the longest application life and the most application is the thin plastering system, but with the passage of time and the improvement of people's housing standards, the external wall insulation technology of the thin plastering system has exposed many problems, and the advantages of the thermal insulation and decoration integrated board system are highlighted, and the thin

Building energy consumption is one of the three "big energy consumers" in China, and exterior insulation is one of the main ways to achieve building energy efficiency. In this situation, the state has put forward higher and higher requirements for the external insulation technology of building exterior walls, which has spawned many external insulation systems using different materials and different structural practices. For example, thin plastering system, curtain wall system and thermal insulation decorative integrated board. Among them, the system with the longest application life and the most application is the thin plastering system, but with the passage of time and the improvement of people's housing standards, the external wall insulation technology of the thin plastering system has exposed many problems, and the advantages of the thermal insulation and decoration integrated board system are prominent, and the advantages are obvious compared with the quality of the thin plastering system. So as a "rising star" insulation decorative board why can go beyond the thin plastering system?

No.1 insulation decoration integrated board construction is more convenient

In the traditional thin plastering system, coatings and thermal insulation materials need to be purchased and constructed separately, and the installation process is complicated. The pre-coated thermal insulation decorative integrated board realizes multi-functional integration, and the factory is the finished board, which can be installed on the wall through "pasting and anchoring. One construction can solve the two functional requirements of heat preservation and decoration, save time and effort, reduce the 5-8 processes of thin plastering system to two, and shorten the whole construction period by half.

No.2 insulation decorative plate decorative effect is more high-end

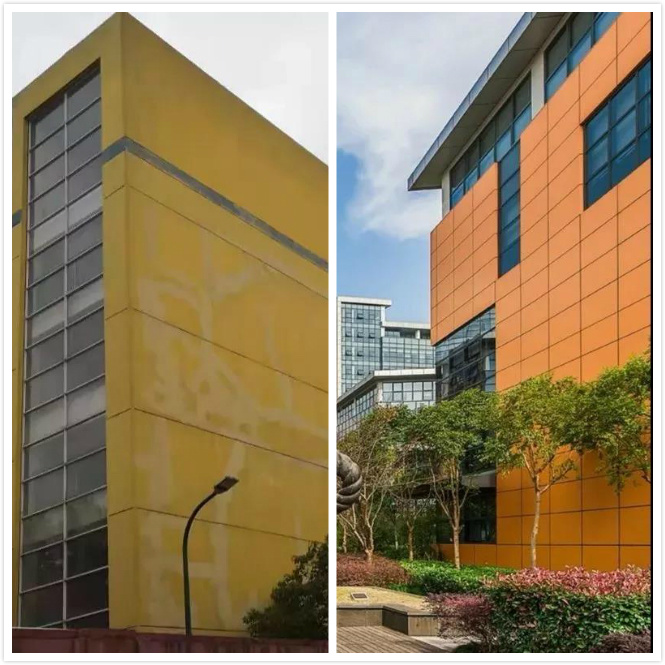

Most of the thin plastering systems use paint finishes with low engineering cost, the flatness is not easy to control, and the surface is easy to crack. And the coating self-cleaning poor, easy to pollution. The insulation decorative board has a unique self-cleaning, such as new after the rain. The characteristics of factory prefabrication make its finish high flatness, rich three-dimensional sense.

Thermal insulation decorative integrated board system diagram

No.3 insulation decorative board with a higher durability

For the building facade system, the most important characteristic is undoubtedly the durability. Because the facade system is the "coat" of the building, it is the only form to express the aesthetic feeling of the building, and it also plays a role in protecting the main structure of the building. Therefore, the durability of the facade system is not only related to the overall aesthetic durability of the building, but also affects the service life of the internal walls of the building to a certain extent.

The durability of the thin plastering system has always been its biggest drawback. It is understood that the thin plastering system has high requirements for adhesives, plastering anti-cracking mortar, grid cloth, putty, coatings and other materials, and it is difficult to match the compatibility and matching of various materials. At present, the market of thin plastering system is chaotic, the product quality is uneven, and the materials produced by various manufacturers can not ensure mutual matching and compatibility, which leads to the quality hidden danger of the whole system.

In addition, the traditional thin plastering system needs to be completed by manual operation, but the thin plastering system has higher requirements on mortar thickness, grid cloth overlapping and operation technology, for example, the gap of insulation board is not more than 1.5mm, the protective layer is 3-5mm thick with alkali-resistant grid cloth, and the grid cloth overlapping cannot be less than 100mm, etc. Because this series of complex processes are completed by manual operation, there are many quality risks. A little improper operation will lead to the whole system can not be fully integrated together, resulting in wall displacement, hollowing, water seepage, cracking, falling off and other quality problems.

A variety of comprehensive factors eventually make the durability of thin plastering system is very short, most projects in three or five years or so will appear serious cracks, pollution, discoloration and so on. At this time, the paint should be repainted to change the visual effect and cover the defects. Therefore, the phenomenon of "bandage building" and "bubble building" which are hotly discussed on the Internet has appeared.

Thin plastering construction site and thermal insulation decoration integrated board construction site

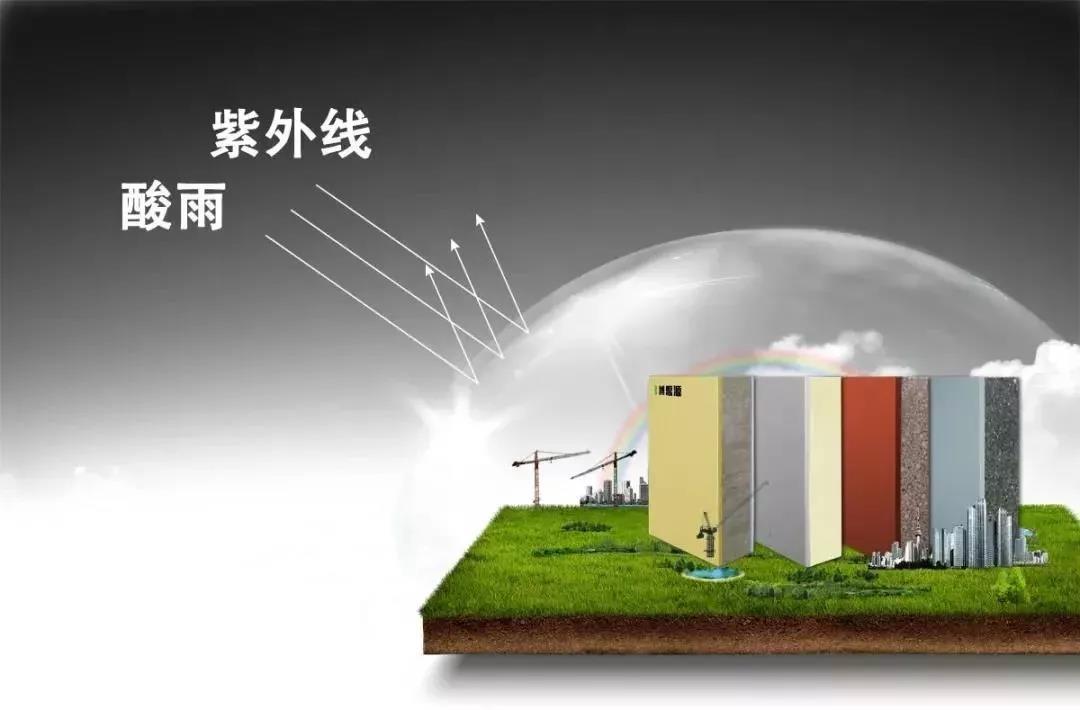

In order to completely eliminate the shortcomings of the short durability of the traditional thin plastering system, the thermal insulation decoration integrated board is "on-line".

The thermal insulation decorative integrated board is a product between the curtain wall and the thin plaster system, which has the decorative effect of the curtain wall and the low cost advantage of the thin plaster system. Insulation decorative integrated board refers to the inorganic insulation material and inorganic pre coated board in the factory, so as to achieve the insulation and decoration function in one of a new type of building exterior wall materials.

As the "upgraded product" of the thin plastering system, the durability of the thermal insulation decorative integrated board is much higher than that of the thin plastering system. In particular, fluorocarbon pre-coated insulation decorative integrated board, its durability can easily reach 3-5 times the thin plastering system.

It is understood that the fluorocarbon pre-coated thermal insulation decorative integrated board facing layer is the fluorocarbon paint with the strongest performance and the longest service life among the coating types as the facing material. The special chemical structure of fluorine resin makes fluorocarbon paint have excellent weather resistance, corrosion resistance, stain resistance and high and low temperature resistance, and it is widely used in many fields. Applied to aircraft, can do aircraft skin coating. In terms of marine coatings, it can be used as an antifouling coating. The heavy-duty anti-corrosion function of fluorocarbon paint has also been used in projects such as sea-crossing bridges and offshore platforms, such as Hangzhou Bay Sea-crossing Bridge and the Three Gorges Project.

Therefore, thanks to the super physical and chemical properties of fluorocarbon paint, fluorocarbon pre-coated insulation decorative integrated board can well resist the erosion of natural factors such as ultraviolet rays, acid rain, dust and haze on the exterior wall, thereby improving its durability.

Moreover, the combination of the integrated board substrate and the fluorocarbon paint makes the service life of the thermal insulation decorative integrated board more durable.

The substrate of the fluorocarbon pre-coated thermal insulation decorative integrated board facing layer is calcium silicate board, and its strength is much higher than that of the plastering mortar composite grid cloth used in the thin plastering system. The impact resistance and wind pressure resistance are strong, and the problems of various outer layer cracks and cracks of thin plastering system are completely solved. And calcium silicate board provides a good "attachment point" for fluorocarbon paint, reducing the occurrence of thermal expansion and contraction, cracking, and will not deform due to temperature changes, freezing and thawing and other factors in the application process. Coupled with the advantages of factory prefabrication, the use of automation equipment fine coating, to maximize the stability of fluorocarbon paint, to overcome the thin plastering system manual operation led to the quality of unstable defects.

To give a more intuitive example, if fluorocarbon coatings are used alone in thin plastering systems, the exterior walls may have different degrees of cracking and fading in less than 10 years. And for the insulation decorative integrated board system, the decorative effect can reach 30 years without obvious visual changes, or even longer.

Speaking of this, the author will give you an analysis of the value of long-life building exterior walls. Let everyone more deeply aware of the importance of long-life exterior wall building materials.

• Long-life exterior wall building materials provide more peace of mind from a household perspective

Generally speaking, the house owner has 70 years of property rights. If the exterior wall cracks due to the increase of service life during the property right period, the worst consequence is undoubtedly water seepage. Water seepage from the exterior wall will directly cause the interior wall to become moldy and become a "big face". In severe cases, people cannot live at all. If it needs to be repaired, it is extremely difficult.

• From the perspective of comprehensive economic costs, long-life exterior wall building materials are more "money-saving"

Take the thin plastering system as an example. The durability of the thin plastering system is up to 10 years. Once it expires, these high-rise buildings will become "naked buildings" without clothes ". For ordinary buildings that require a design life of 70 years, the main body of the building needs at least 4-5 exterior wall renovations in its lifetime. This will be a huge project and the cost will be immeasurable. The fluorocarbon pre-coated thermal insulation decorative integrated board, a typical "long-life" exterior wall building material, can relatively reduce 2-3 times of repair and reconstruction, and greatly reduce the "repair" cost.

• From the perspective of environmental resource utilization, long-life exterior wall building materials are more environmentally friendly

Take specific events as an example, we must have heard of the renovation of old residential areas released by the state this year. On July 1, the Ministry of Housing and Urban-Rural Development, the National Development and Reform Commission, and the Ministry of Finance issued the "Notice on Doing a Good Job in the Reconstruction of Old Communities in 2019" to improve people's livelihood needs. The renovation projects include public equipment renovation, exterior wall renovation, and environmental renovation. According to relevant statistics from the Ministry of Housing and Urban-Rural Development, there are nearly 160000 old communities across the country, involving hundreds of millions of residents, more than 4200 households, and a construction area of about 4 billion square meters.

As can be seen from the data, there are a large number of old residential areas that need to be renovated. With such a large-scale renovation project, it is not difficult to imagine how much construction waste will be produced. With the rapid development of urbanization, it is inevitable to demolish and rebuild old buildings, but if short-lived exterior wall building materials are always used, it means that there will be more large-scale renovation projects in the future.

In other words, only by developing long-life exterior wall building materials can it be possible to reduce environmental pollution caused by construction waste in the future by reducing the number of renovations.

In summary, it can be concluded that the use of long-life exterior wall building materials can not only effectively extend the life of the building, ensure the durability and structural safety of the building, but also "more peace of mind, more money, more environmentally friendly".

Keywords:

Energy saving wuhan, energy saving wuhan calcium silicate board, china building materials group calcium silicate board

Latest Updates

Contact Information

Phone:027-65521781(Office phone)

027-65521935(Calcium Silicate Board Division) /027-65522625(Decorative Panel Division)

Email:baifeng@sinoma-ec.cnlijie@sinoma-ec.cn

WeChat Official Account

WeChat Video Channels

Official TikTok

Product Color Chart