The most detailed external wall insulation board construction technology

Release date:

2021-08-01

Author:

Source:

External Wall Insulation Alliance

Construction technology of external wall thermal insulation integrated board

1. construction process

1. Process flow

Basic inspection-basic wall hollowing, falling off and leveling treatment-elastic reference line and division-paste insulation decorative board-use special fasteners to hinder the solid decorative board-use insulation foam strip to fill joints-clean the gaps in the board-paste masking tape-pour silicone weather-resistant sealant-install special exhaust plug-tear off masking paper-clean the panel

2. Construction sequence

Longitudinal construction is generally carried out in the order from bottom to top, but in order to ensure that each board is on the same horizontal line on the surrounding walls, the same datum line on the surrounding walls of the building should be taken as the starting point upward and downward. Horizontal construction shall comply with the first positive angle and then the negative angle. First ensure the special structure (such as the symmetry and uniformity of doors and windows), and then large-scale construction.

The adjustment treatment method shall be determined according to the measurement results. If the deviation is too large, the design size shall be adjusted. The design unit shall negotiate with the owner to propose changes, and the owner shall implement the changes after confirmation.

Key points of 2. construction

1. Installation requirements for hanging basket

The hanging basket construction can be adopted for the thermal insulation decorative board system, and the specific requirements are as follows:

Hanging basket installation: The installation of the hanging basket must comply with safety regulations, and the inner side of the hanging basket must be installed with elastic spacers to avoid damage to the installed decorative panels when the hanging basket is lifted.

2. Requirements for base plastering

The base plastering layer shall be free of blistering and sand dropping, and the plastering quality shall reach the intermediate plastering standard. Requirements for flatness and verticality: check with a 2-meter ruler and control within 4mm; The straightness of yin and yang angles at the grass-roots level shall be measured with a 2-meter ruler, and the gap between exposed joints shall not be more than 5mm.

3. Put the baseline

The reference line refers to the initial construction line in the vertical and horizontal directions as the starting point after the construction starts, and the standard line that keeps the relative positions of the graphics of the four walls unchanged. Generally, the longitudinal reference line of construction shall be placed on the top of the building, while the transverse reference line of construction shall be placed on the contour line of yin and yang angle and the contour with characteristics as the reference line. All reference lines shall be occupied for construction.

In the thermal insulation decorative board system, the reference line is first placed on the construction wall surface according to the design drawing, and the longitudinal and horizontal reference lines are bounced on the wall with ink lines. Each connecting construction surface shall be flicked.

4. On-site bullet line principle

According to the layout chart;

Ensure economic principles;

Ensure the aesthetic principle;

Ensure safety principles.

5. Technical requirements

All elevation horizontal lines, vertical lines must first determine a datum start line, and then lead the datum start line to each elevation. Finally, several control lines are determined on each facade according to the drawing style, which is convenient to control and ensure the minimum error of plate installation during the setting-out process. At the same time, when playing the line, we must play the double line to ensure that the plate and the plate seam are within the control range. After playing the line, it must be reviewed repeatedly, and the next process can only be carried out after many reviews.

6. Scope of Control

Verticality: the error with height less than 30m should be guaranteed within 10mm; The allowable error greater than 30m and less than 60m should be guaranteed within 15mm; The allowable error greater than 60m and less than 90m should be guaranteed within 25mm. (theodolite inspection).

Lean degree: the height of less than 3m should be less than 3mm; The height of more than 3m should be less than 5mm.

Straightness: if the length is within 30m, it should be within 5mm; The allowable error of length greater than 30m and less than 60m should be guaranteed within 10mm; The allowable error of more than 60m and less than 90m should be guaranteed within 15mm. (Check with straight line and steel ruler).

7. Inspection methods

Level test using level measurement, if the use of horizontal pipe to the construction must be repeated after the construction, in order to ensure the construction quality. The verticality is measured by theodolite. If the wire hammer is used to hang the wire, the weight of the wire hammer must be determined according to the height to ensure that the vertical line is not affected by the wind. And should also go through multiple reviews before the next process.

Self-inspection stage before installation of 3. insulation decorative panel

Before installing the thermal insulation decorative board, it is necessary to carefully check whether the flatness of the wall is within the required range (the error must be less than 2mm, and the external quality of the board must be detected by 2m guiding ruler and feeler gauge). If the board is not qualified, it is strictly prohibited to use the board (the inspection contents include color difference; Flatness; Whether there are scratches on the surface of the insulation board and other items that affect the appearance and use function).

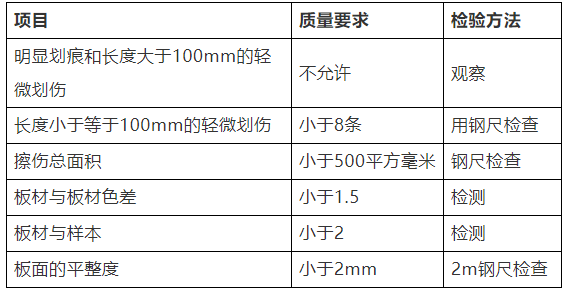

The following is the surface quality and inspection method of thermal insulation decorative board per square meter shall conform to the following table

Installation stage of 4. fixed-length thermal insulation decorative board

1. Installation principle for fixed-length insulation decorative board

The thickness of the fixed-length thermal insulation decorative board must meet the design requirements;

The color of the fixed-length thermal insulation decorative board must meet the design requirements;

The connection between the fixed-length thermal insulation decorative board and the wall must be firm and reliable;

Fixed-length installation must take into account the economic and aesthetic principles;

The installation error of fixed-length thermal insulation decorative board must meet the requirements of quality specifications.

2. Fixed-length thermal insulation decorative board and installation technical requirements

Before installation, the fixed-length thermal insulation decorative board must carefully check whether each fixed-length board has quality problems, and the fixed-length board with problems must be picked out (e. g. bubbles; board angle deformation; serious scratches; serious color difference; the thickness of the fixed-length board does not meet the design requirements, etc.);

The fixed-length thermal insulation decorative board must be installed firmly and reliably;

When the size of any side of a single board is less than 300mm, it can be symmetrically fixed on the long side. When the size of both parallel sides of the board is greater than 300mm, it must be fixed around;

When installing the fixed-length thermal insulation decorative board, the problem of closing treatment of special parts must be considered at the same time. Such as: the window side should pay attention to the problem of anti-leakage, the window side of the aesthetic problem, whether to achieve mass installation, etc;

3. Scope of Control

Verticality: the error with height less than 30m should be guaranteed within 10mm; The allowable error greater than 30m and less than 60m should be guaranteed within 15mm; The allowable error greater than 60m and less than 90m should be guaranteed within 25mm (theodolite inspection);

Lean degree: the height of less than 3m should be less than 3mm; The height of more than 3m should be less than 5mm;

Straightness: if the length is within 30m, it should be within 5mm; The allowable error of length greater than 30m and less than 60m shall be guaranteed within 10mm; The allowable error greater than 60mm and less than 90m shall be guaranteed within 15mm (check with straight line and steel ruler).

4. Inspection methods

Installation flatness of thermal insulation decorative board: check with 2 m guiding rule and feeler gauge, which should be less than mm;

Installation verticality of thermal insulation decorative board: check with 2m guiding rule and feeler gauge, which should be less than 2mm;

Installation levelness of thermal insulation decorative board: check with 1 meter level, which should be less than 1mm;

Corner dislocation of adjacent plates: it should be guaranteed within 1mm. Inspect with level ruler;

Yang angle square: should be guaranteed within 2mm. Check with angle ruler; steel ruler;

Joint height difference: because the guarantee is within 1mm. Check with steel ruler;

Straightness of joint: the error shall be within 3mm within 5m, and the straight line shall be checked with steel ruler.

5. fixed insulation decorative plate

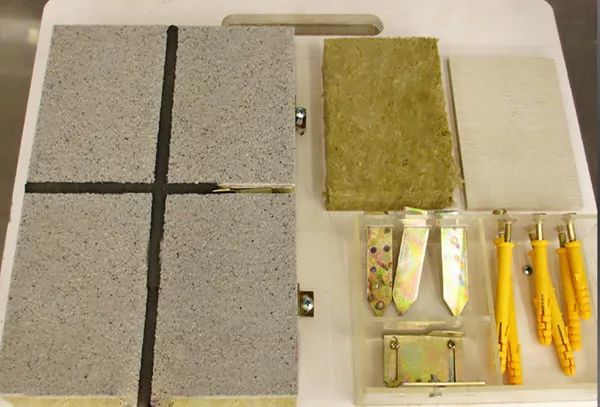

1. Paste the thermal insulation decorative board

The adhesive adopts special adhesive mortar, and the back of the thermal insulation decorative board is arranged by point sticking method. The arrangement requirements of bonding points are as follows:

There are not less than 5 bonding points per board and the bonding area is not less than 40%.

The adhesive layer compression setting thickness is 3-8mm.

First of all, the deployment of uniform special adhesive mortar with a point coated on the back of the insulation decorative board. The diameter of each coating point is> 50mm, push the thermal insulation decorative board on the base layer by hand, and then adjust the position of the thermal insulation decorative board to keep the overall board surface flat and align the grid joints (it is strictly prohibited to knock the board surface during construction).

The specific quality requirements are as follows:

The flatness of the whole plane is less than 2mm, measured with a 2m ruler, and the height difference of the plate seam is less than 1mm;

Ensure that the bonding points within each square meter shall not be less than 5, and the diameter of each coating point shall not be less than 50mm,

The position shall be horizontal, flat and vertical, and arranged in order.

Detection method:

Use a ruler to lean on the bonded board surface, and then use a race ruler to measure the size of the gap;

Use a small wooden hammer to lightly hit the board surface, and judge the size of the paste area and the number of paste points according to the degree of emptiness;

Visual method.

Special fastener for 6. installation

The thermal insulation decorative board system is pasted and needs to be fixed after the position is determined. The special anchor is the insulation layer and the panel are protected at the same time;

Use special tools to cut grooves on the side of the lining panel. In order to match the installation of special fasteners, control the milled edge length of 50~80mm, the milled edge width of 2mm (including seam width, evenly distributed on both sides), and the milled edge depth of about 10mm.

Use special fasteners to fix the thermal insulation decorative board on the wall.

Quality requirements: the maximum distance of special fasteners is ≤ 500mm, the distance between special fasteners and the top of the board edge is ≤ 180mm, the distance between special fasteners and the corner of the wall edge is ≥ 100mm, and the special fasteners are fully installed. Moderate pressure.

Detection method: visual method

7. sticker tape

Clean the surface of the application board with special cleaning agent, and stick the paper tape according to the requirements of the grid width.

8. caulking

After the thermal insulation decorative board is fixed, the gap between adjacent plates is filled with thermal insulation foam strips to further heat preservation and save silicone weather-resistant sealant.

9. special silicone weather-resistant sealant

1. Glue stage

First, use a sealing gun to evenly apply a proper amount of sealant to the split seam, and then use a flat scraper to scrape the sealant. It is required that the thickness of the special silicone weather-resistant sealant on the board is 0.5-1mm, and the width can just cover the special fastener. After the glue is applied, the paper tape should be pulled off.

2. Technical requirements

The plate must be cleaned before gluing to ensure that the silica gel meets the following requirements,

The joint glue of the plate should be full, dense, continuous, uniform, without bubbles, and the width and thickness should meet the design requirements and technical standards.

3. Scope of Control

Before the board is glued, the board seam must be cleaned to ensure that the silicone does not bubble; Smooth and other requirements.

The joint glue of the board should be less than one bubble within two square meters;

In the range of ten square meters, the silica gel basically meets the requirements of full, dense, continuous and uniform.

4. Inspection methods

Straightness: if the length is within 30m, it should be within 5mm; The allowable error of length greater than 30m and less than 60m should be guaranteed within 10mm; The allowable error of more than 60m and less than 90m should be guaranteed within 15mm. (Check with straight line and steel ruler)

Bubbles; smoothing, etc. can be observed.

Waterproof can be carried out for water spraying inspection

10. surface cleaning

First clean the dust and dirt on the edge of the thermal insulation decorative board, then tear off the protective film, and then remove the viscose residue with a clean towel. If the insulation decorative board is locally glued with cement, the sand ash should be washed with clean water.

Quality requirements: no stain, no dirt

Detection method: visual method

XI. Finished Product Protection

1. Thermal insulation decorative board

Avoid direct sunlight

Keep away from fire sources, and there shall be no open fire or electric welding nearby.

Keep away from organic solvents such as petroleum hydrocarbons

termite-free living area

Lay horizontally to prevent deformation from tilting or bending under pressure

Prevent extrusion or impact of heavy objects and puncture of sharp objects.

2. Special inorganic adhesive

Placement area: dry, cool and ventilated

Tight packaging, lined with polyethylene film waterproof and moisture-proof, clear label on the packaging bag

The packaging bag mouth of unused materials needs to be tied tightly to prevent the exposed mouth from being placed.

3. Construction tools

Equipped with special construction tools for external insulation system

Management and maintenance of special tools

Cleaning and maintenance of special tools

Note: 1. After the thermal insulation decorative board is pasted, temporary protective measures shall be taken for the part that may cause pollution due to subsequent works.

2. Temporary protective measures shall be taken for the population, passage, sun corner and other parts that may collide during construction.

XII. Acceptance

1. Quality acceptance of decoration engineering of thermal insulation decorative board system

It shall comply with the standards for the installation and acceptance of decorative panels in the GB502102014 Code for Quality Acceptance of Building Decoration Engineering.

2. The construction process and quality inspection documents shall include:

Project design documents, design change documents, negotiation records, etc.

Product certificate, inspection report, product specification.

Binder inspection report.

Construction technical disclosure documents.

Construction process records and construction quality inspection records and process progress documents signed by the supervisor or Party A's representative.

The copy and copy of the construction documents of the thermal insulation decorative board system shall indicate the original storage unit, endorse the name of the copy or copy person and affix the official seal.

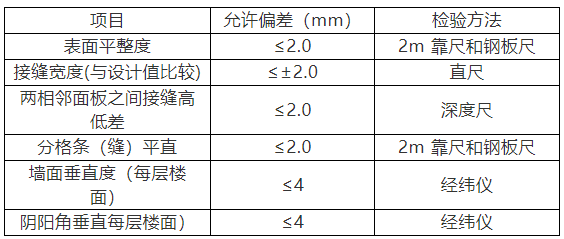

See the following table for allowable installation deviation and inspection method of thermal insulation decorative board system:

Allowable deviation of installation dimension and inspection method (Table 1)

3. The physical appearance inspection of the project shall meet the following requirements

The variety, specification, color, pattern and pasting method of the thermal insulation decorative board shall meet the requirements.

The thermal insulation decorative board system must be firmly pasted and reliable.

Thermal insulation decorative board system surface should be flat, clean, no skew and cracks.

At a distance of about 3m from the board surface, visually observe that the color of the board surface should be uniform and free of flowers.

Joints shall be continuous, straight, smooth and densely packed.

Keywords:

Latest Updates

Contact Information

Phone:027-65521781(Office phone)

027-65521935(Calcium Silicate Board Division) /027-65522625(Decorative Panel Division)

Email:baifeng@sinoma-ec.cnlijie@sinoma-ec.cn

WeChat Official Account

WeChat Video Channels

Official TikTok

Product Color Chart